HYDRO SILK

Hydro Silk™ is the ultimate high performance coating for your vehicle—delivering deep, reflective gloss with the durability of 20% SiO₂. It forms a flexible, high-temp-resistant shield that repels UV, grime, rubber, and chemicals without streaks or buildup. Safe on wraps, PPF, carbon fiber, and custom finishes, it’s your go-to for race-ready protection and effortless maintenance.

Full Description

The Future of Paint Protection

Hydro Silk™ is the ultimate wax replacement for drivers who demand more from their machines. Built with Nano-Crystal Technology and 20% SiO₂, it delivers the ultra-deep gloss of a show car, the chemical resistance of a ceramic, and the ease of a wax-on application—no streaks, no buildup, and no risk to wraps, carbon fiber, or custom finishes.

Unlike brittle coatings that can crack under high temps and chassis flex, Hydro Silk cures into a flexible, high-density shield that stands up to UV, oxidation, brake dust, rubber, fuel, and track grime. It’s safe on vinyl wraps, PPF, matte finishes, and high-temp surfaces—perfect for exotics, track cars, time attack builds, and canyon-carving machines.

✔️ Track-Tested Durability (Up to 1 year of protection)

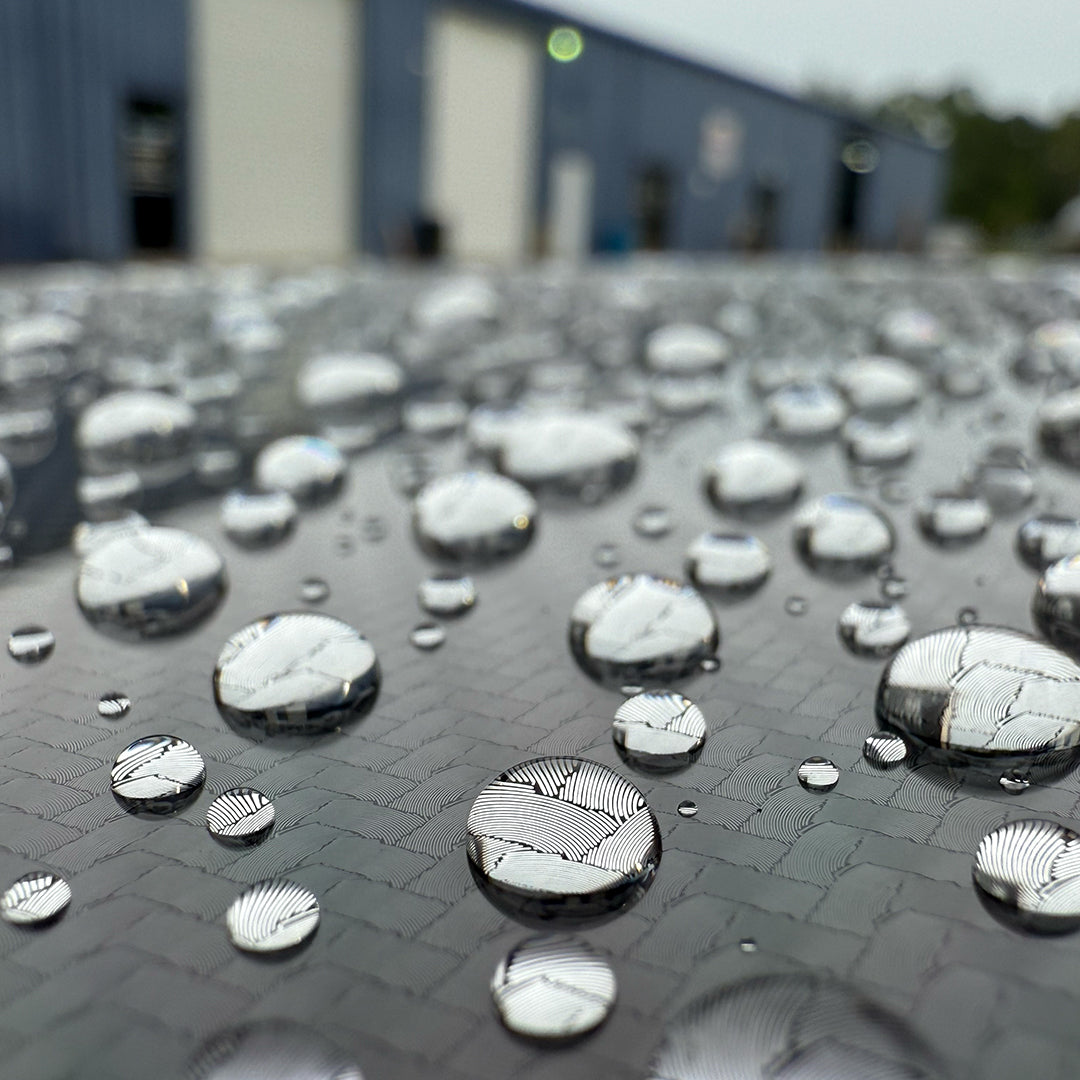

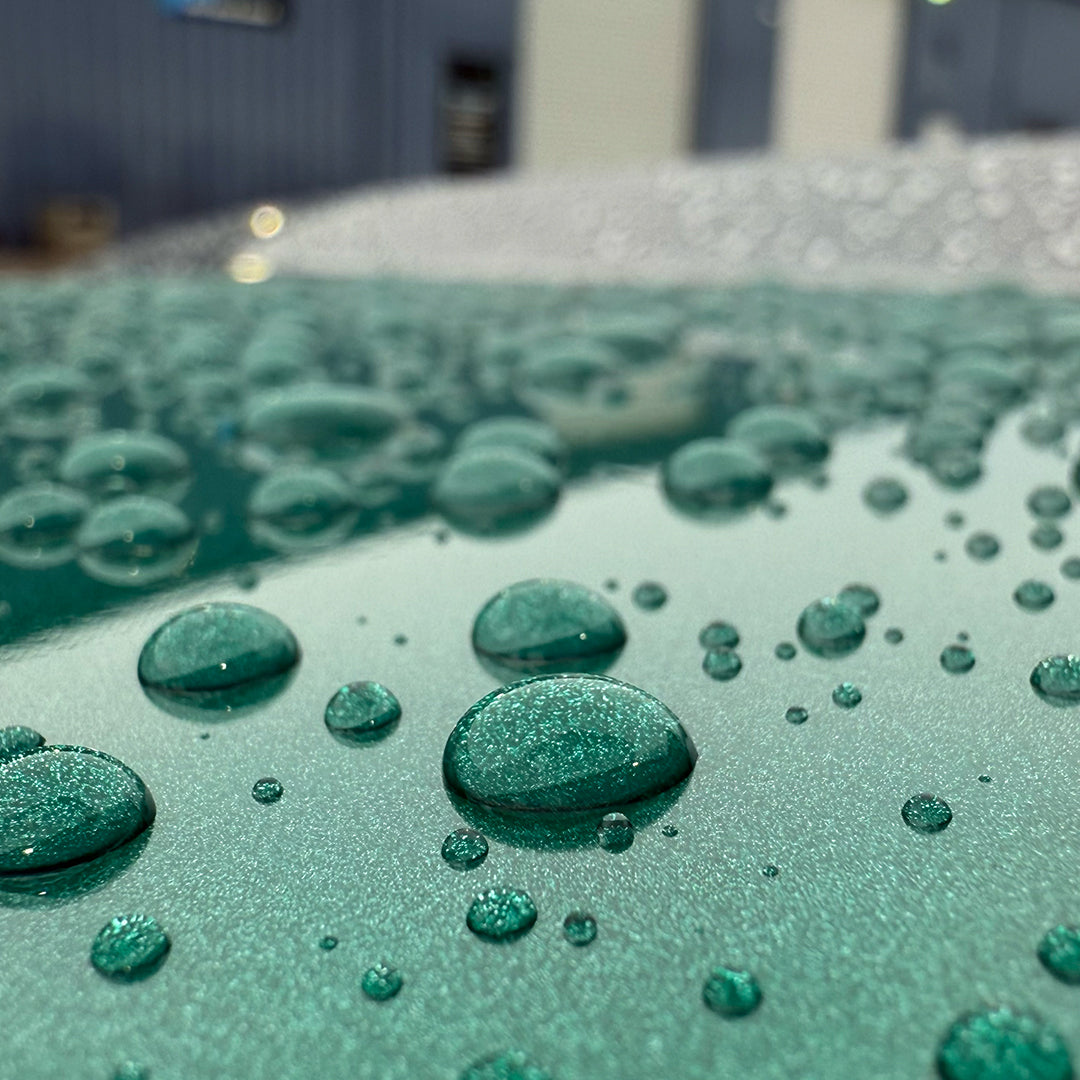

✔️ Ultra-Hydrophobic Sheeting for Quick Cleanups

✔️ UV Shielding to Prevent Fading & Oxidation

✔️ Wrap-Safe & Ceramic Coating Compatible

✔️ Deep, Reflective Gloss That Commands Attention

Whether you’re chasing podiums or polishing your weekend weapon, Hydro Silk™ keeps your finish flawless and race-ready. Apply every season for unmatched shine and protection.

30-Day Risk-Free Trial

Fast shipping & Free Returns

HYDRO SILK

Key Benefits

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Try it for 30 Days. Satisfaction Guaranteed.

If you don't love it, you receive a full refund. No questions asked.

🏅 30-DAY MONEY BACK GUARANTEE

Full list of benefits

Sacrificial Layer Protection

Acts as a protective layer to safeguard long-term coatings, clearcoats, gelcoats, plastics, glass, decals, and synthetic leathers, preserving their integrity.

Non-Permanent Adherence

Gradually dissipates over time, ensuring no permanent adhesion or damage to the underlying surface.

Lasting Protection

Hydro Silk delivers up to 6 months of peak performance with intense gloss & hydrophobic properties, followed by continued surface protection that lasts up to 1 year.

SiO₂ Meets Wax-Like Application

Combines wax-like ease with durable, high SiO₂ protection—no wax inside. Safe in direct sun, buffs off effortlessly, and protects plastics from fading.

20% SiO₂

Hydro Silk leaves behind a true 20% SiO₂ surface layer—the same level found in many long-term ceramic coatings giving you ceramic performance in a non-permanent, easy-to-apply coating.

Structure

Hydro Silk is built on a nano-crystal lattice structure integrated within a densely crosslinked SiO₂ matrix. This architecture minimizes microvoids, increases structural uniformity, and stabilizes the coating at the molecular level.

UV Protection

Hydro Silk protects against UV through a layered structure: the SiO₂ matrix reflects and scatters radiation, while the nano-crystal lattice refracts and disperses light. UV-stable crosslinking converts harmful energy into heat, preventing surface degradation without migratory additives.

Healing Ceramic Coatings

Hydro Silk restores ceramic coatings by locking into microvoids, stress cracks, and fissures. Its reactive SiO₂ structure then chemically bonds to the existing ceramic, fusing gaps and rebuilding structural integrity—restoring the coating to better-than-new gloss and hydrophobics.

Hydrophobic Properties

Provides industry-leading water repellency and beading, ensuring surfaces remain clean and protected.

Enhanced Gloss

Adds a deep, reflective gloss to any surface, enhancing long-term coatings or acting as a stand-alone gloss enhancer.

Versatile Use

Can be applied to any surface on a vehicle, from the clear coat down to the rims; all metal, plastic, glass, trim, paint, and more.

Fast. Easy. Long-Lasting Protection

How it works

1.) Apply with Applicator Pad

2.) Let Acclimate

3.) Buff with Microfiber Cloth

Instructions

Surface Prep

- Ensure the surface is clean and dry.

- Polishing is not required, though it may enhance visual clarity. Hydro Silk is a non-permanent coating and does not depend on surface correction.

- For glass, use a water spot remover beforehand if needed.

Buff On

- Use only a foam wax applicator pad.

- Prime the pad with 5 pumps spread into the pad evenly to fully lubricate it.

- After priming, apply 1 pump per 2 sq. ft. of surface.

- Lightly dab the area 4–5 times before buffing — this helps evenly distribute the product across the work area.

- Buff in circular motions until the product is spread in a uniform, thin layer.

- Apply thinly to avoid waste — excess will be buffed off later.

- Hydro Silk can be applied to the entire vehicle before buffing off, as long as the environment is clean.

This product can be applied in direct sunlight without issue.

Dwell Time

- Allow the product to sit for at least 5 minutes after buffing on.

- Ideal dwell time is 15–30 minutes.

- Longer dwell times even over an hour is safe under most conditions.

Buff Off

- Use a clean, lint-free microfiber towel.

- Buff in circular motions until no visible residue remains and the surface feels smooth.

Curing

Hydro Silk cures in stages:

- Initial protection is active within the first hour

- Full cure is reached in ~3 days

To optimize longevity:

- Keep the surface dry for 8 hours

- Avoid washing for 3 days

- Use only pH-neutral soaps during routine washing

Early washing or exposure to harsh chemicals won’t cause failure but may reduce hydrophobics or shorten lifespan depending on severity. Hydro Silk was torture-tested for durability and can withstand immediate exposure to a brush style automatic car wash with no loss of hydrophobic properties—but we still recommend avoiding them and following our guidelines for the best long-term user experience.

FAQs

Please read our FAQs page to find out more.

What makes HYDRO SILK™ unique?

Hydro Silk is a true all-in-one solution—designed as a standalone coating for every surface of the vehicle, a dedicated ceramic topper that chemically heals and restores long-term coatings to better than new, and a PPF conditioner that protects against fading and cracking for years.

How is HYDRO SILK™ made?

At the core of Hydro Silk’s performance is its integration of a robust SiO₂ matrix, a crystal lattice structure, and advanced cross-linking technology. Together, these elements create a cohesive, high-strength network that protects surfaces while enhancing their appearance.

How long will it last on my vehicle?

Hydro Silk provides up to 12 months of protection for paint, ceramic coatings, and PPF, delivering complete care in one advanced formula. For premium clients who demand peak performance and a flawless finish year-round, we recommend reapplying every 6 months.

Is it easy to apply?

Hydro Silk Coating is as user-friendly and fail-proof as it gets, applying with a simple “wax on, wax off” process that works for all skill levels. It can be applied on hot surfaces up to 150°F and still buffs off cleanly—even after sitting for hours—making it one of the most forgiving coatings available.

How long does it take to cure?

Hydro Silk undergoes a structured curing process for immediate protection and long-term durability. True SiO₂-based coatings require 3–4 days to fully cure. While Hydro Silk offers reliable protection after just one hour, avoid washing or exposing it to harsh chemicals for 72 hours to ensure longevity and optimal results.Exposure to washing or harsh chemicals during this period won’t cause failure but may slightly reduce hydrophobicity and longevity depending on severity. Hydro Silk was torture-tested at the 30-minute mark to ensure foolproof performance.

How do I maintain my vehicle after application?

Hydro Silk’s anti-adhesion properties make routine maintenance effortless—most dirt and debris rinse off with minimal effort. For regular cleaning, a quick rinse is often enough, while full washes should be done using a pH-neutral soap with a soft mitt or towel, or a touchless system to preserve the coating’s integrity.

What sets HYDRO SILK™ apart from wax?

Hydro Silk delivers the deep gloss, effortless application, and surface safety wax is known for—while eliminating everything that holds traditional and hybrid ceramic waxes back. It doesn’t melt, fade, or break down under stress. Instead, it forms a durable 20% SiO₂ coating that resists extreme temperatures, prevents UV damage, and protects up to 10x longer. Safe on all exterior surfaces and easier to apply than most waxes, Hydro Silk makes both traditional and hybrid ceramic waxes obsolete.